News/Innovations/Information

2019 – New Rotational-Lining-Plant expands the opportunities of Rudolf Gutbrod GmbH

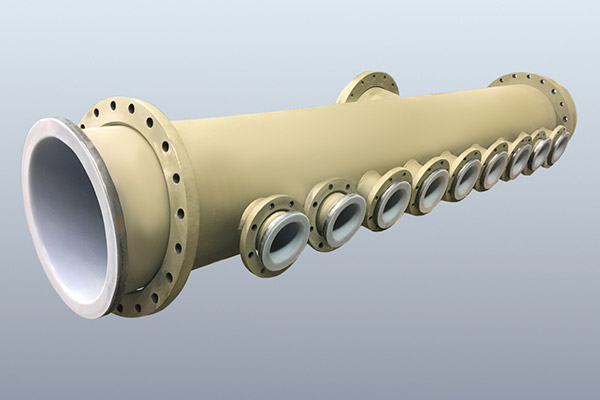

ChemResist Rotational-Lining established within the last years as a highlight in the lining industry.

The conventional lining and coating techniques that are currently on the market, often do not meet the diverse requirements.

ChemResist puts a new emphasis in this case using a process and computer-controlled lining technology according to the rotational sinter lining process. This procedure creates a seamless lining with virtually uniform lining thickness.

- Lining-technologies for highest standards

- Seamless linings for almost every shape

- Superior adhesion to metal substrates

- Excellent permeation property due to the use of fillers, compared to commercially Fluoropolymer-linings

With our new rotational-lining-plant we are able to line bigger components. Advantages are

- Vacuum resistance

- Temperature resistance

- Universal chemical resistance

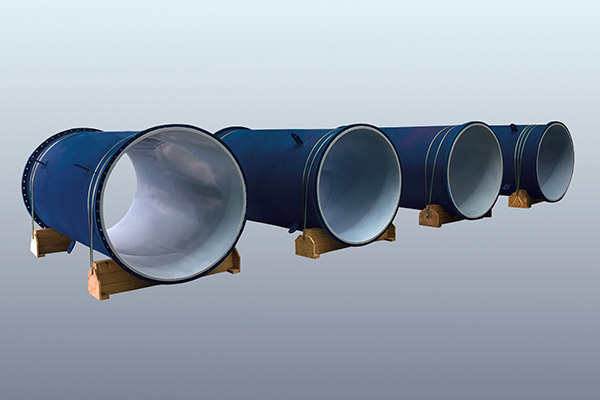

From now on we are able to line components with this method without fixed requirements regarding constructions up to following dimensions (depending on the geometry):

- Length up to 3200 mm, depending on the diameter

- Diameters up to 2500 mm

- Weights up to 2300 kg

- Bigger and heavier parts on demand